25.1 Overview of Product Flow Model

| Topic Version | 1 | Published | 12/09/2016 | |

| For Standard | PRODML v2.0 | |||

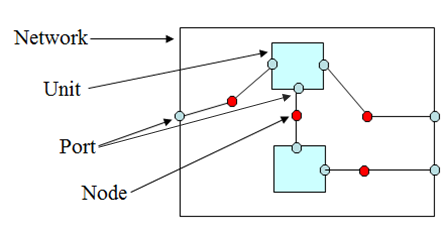

The Product Flow Model data object can be used to define a directed graph of flow connections (Figure 25.1-1). The basic building block is a Unit which can be used to define the flow behavior of any facility (where the term facility represents any use of equipment to perform a function) such as a separator, a wellhead, a valve, a flow line. It uses a general hierarchy of:

Model (collection of networks)

Network (collection of connected units)

Unit (black box with ports)

Port (allows flow in or out)

Node (allows ports to connect)

The Network represents the internal behavior of the model or a unit in another network and is a collection of connected units. A Unit is essentially a black box that can represent anything (big or small). Ports allow flow in or out of a Unit. Nodes are used to connect ports.

In any given Product Flow Model, the following is assumed:

- Steady state fluid flow across nodes and ports. That is, pressure is constant across internally and externally connected ports and nodes.

- Conservation of mass across a node or port.

- Pressure can vary internally between ports on a unit.

- Connections between models should be one-to-one so that mass balance concerns are internal to each model.

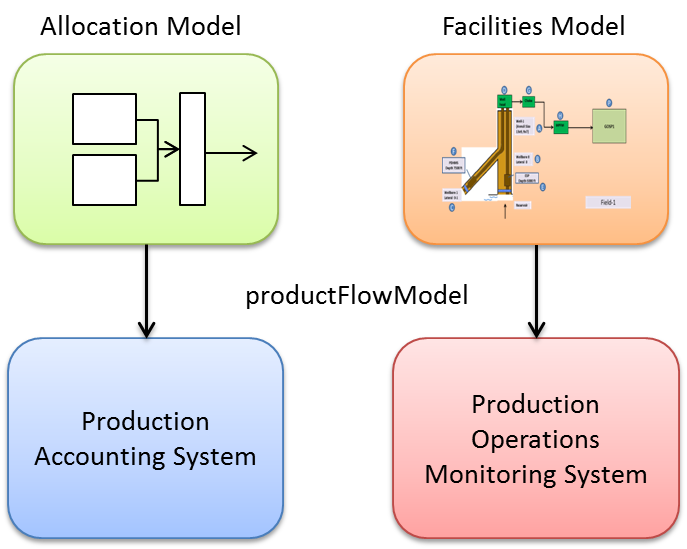

A variety of models may be created and used for different systems (Figure 25.1-2). For instance, a production accounting system will have a different model than a production operations dashboard that is used to monitor real-time data from a facility. However, by using PRODML, these various models may be exchanged using the same standard format.

Note that Product Flow Model is also used in the Optical Path object (see 14.3 Defining the Optical Path ) in distributed sensing (DTS and DAS), to show the connection of the components in a fiber optical path.