28.1 Production Operation Data Object Overview

| Topic Version | 1 | Published | 12/09/2016 | |

| For Standard | PRODML v2.0 | |||

The Production Operation Data object is a further companion to the product volume object described in Chapter 24 Product Volume . It enables the exchange of production operation data along the lines of a “morning report” for production operations. The volumes would be expected to be transferred using product volume.

Production operation has an offshore operation orientation, reflecting its origins in the Norwegian Continental Shelf reporting requirements.

Production operation has a set of identifying elements and common elements, and then has a repeating Installation Report element. This identifies the installation, so that one transfer can deal with a number of related installations, and then it contains the following categories of data:

- Count of crew, by crew type and beds available.

- Work hours performed day, month and year to date.

- Production operation HSE (see below).

- Production operation activity (see below).

Production operation HSE is a list of statistics concerning HSE such as number of incidents, time since last incident, and similar. It also contains a weather report with detailed weather attributes.

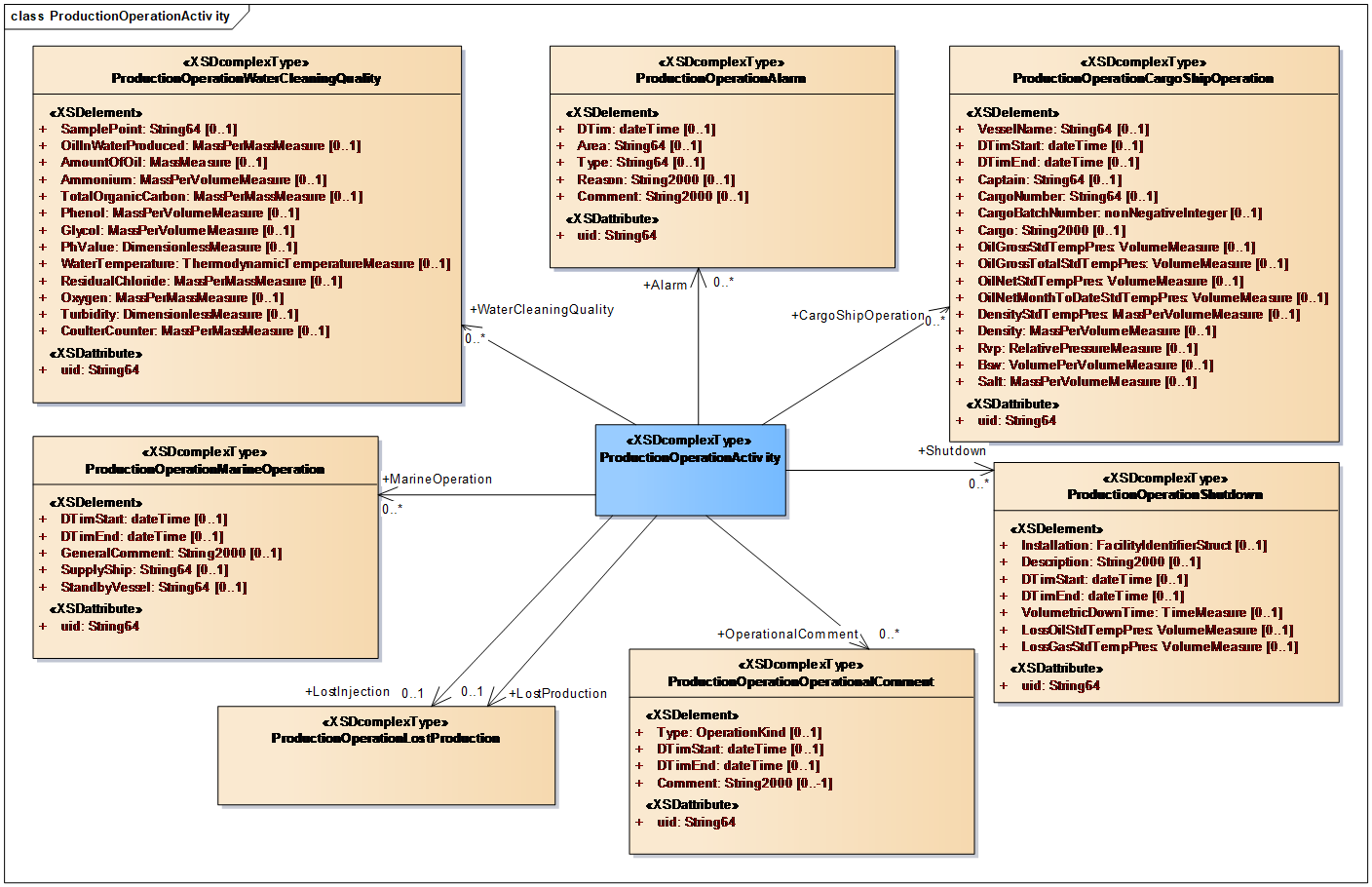

Production operation activity is a more detailed capability to report operational activity in a number of areas:

- Water quality

- Alarms

- Cargo ship operations (which includes volumes loaded, duplicating a part of product volume, but from the perspective of an operational report rather than a hydrocarbon accounting requirement).

- Marine operations (supply and standby vessels and related).

- Shutdowns (including time, duration, loss of oil and gas production).

- Lost production (which can also be referred to as deferred production since it is not “lost” in the usual sense of the word: in SPVR, deferred production was the term used; see 6.3.2 Worked Example Volumes Walkthrough , item 8). This element has a volume lost amount, and also an enum list of reason for loss. In SPVR this enum was not listed since it was understood that each company would have its own set of reason codes. The enum values reflect agreed values for NCS reporting.

- Comments on operations, which are typed by an enum list.

For the UML diagram of production operation activity, giving a good overview, see Figure 28.1-1 .